Top 10 Electric Ball Valves You Need to Know About?

Electric Ball Valves are becoming increasingly important in fluid control systems. Experts in the field recognize their growing significance. For example, John Driscoll, a leading authority on valve technology, once stated, "Electric Ball Valves are the future of efficient flow control." This statement highlights the potential of these devices in various industries.

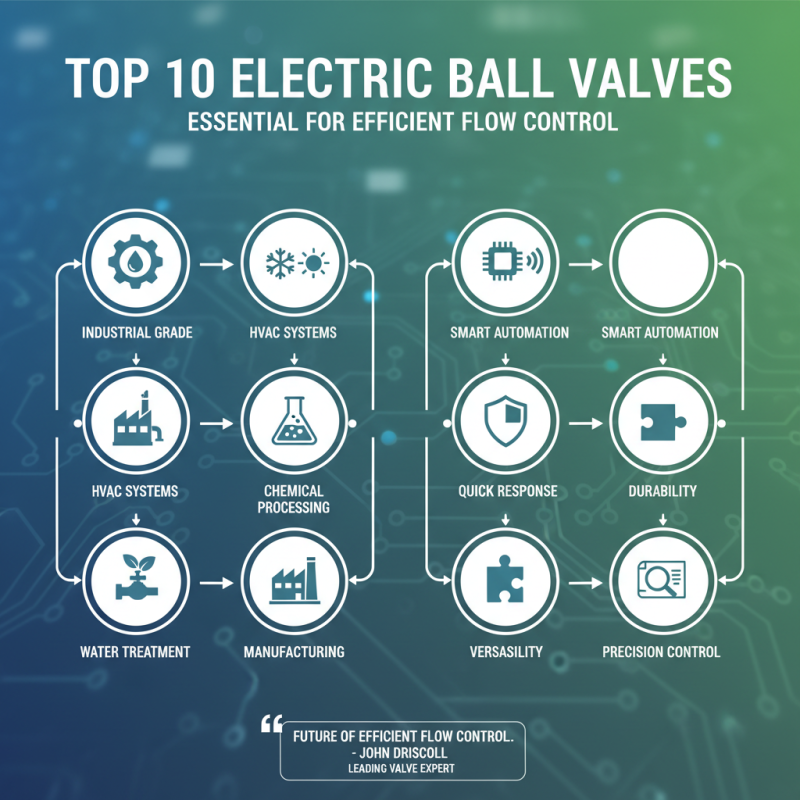

The versatility of Electric Ball Valves is remarkable. They deliver precise control and quick response times. In sectors like chemical processing and HVAC, reliable valves are essential. Engineers often face challenges in selecting the right valve for their applications. It can be difficult to navigate the many options available.

Choosing the best Electric Ball Valves requires careful consideration. Performance, durability, and compatibility are crucial factors. Yet, there’s always room for improvement. Understanding the specific needs of a project can help in making the right decision. This overview of the top 10 Electric Ball Valves aims to provide insights into this evolving technology.

Overview of Electric Ball Valves and Their Applications

Electric ball valves play a crucial role in many industrial and domestic applications. They use electricity for operation, providing precise control over fluid flow. These valves consist of a ball with a hole in the middle. When the valve is open, the hole aligns with the pipeline, allowing fluid to pass. When closed, the ball blocks the flow completely. This simple yet effective design contributes to their widespread use.

Applications of electric ball valves vary widely. They are commonly found in water treatment plants, HVAC systems, and chemical processing. In these settings, they ensure efficient and safe operation. Their ability to automate processes reduces manual labor. However, reliance on electronic components can be a double-edged sword. If the power fails, the system may stop functioning. Regular maintenance is essential yet often overlooked. Without it, even the best designs can fail unexpectedly.

The versatility of electric ball valves comes with certain challenges. Choosing the right valve for a specific application demands careful consideration. Factors like pressure, temperature, and medium type must all be accounted for. Misjudgments can lead to inefficiencies and safety hazards. Awareness of these factors is vital for successful implementation. Often, a deeper understanding is needed to avoid costly mistakes.

Key Features to Consider When Choosing Electric Ball Valves

When selecting electric ball valves, several key features stand out. First, consider the valve's material. Common materials include stainless steel, brass, and PVC. Each has specific compatibility with different fluids and environments. According to industry reports, about 40% of valve failures stem from material incompatibility. This detail can significantly impact the longevity of the valve.

Moreover, the actuator type also matters. Electric actuators can be subdivided into two main categories: on/off and modulating control. About 60% of users prefer on/off actuators for their simplicity. However, modulating types offer more precise control, which is critical in sensitive applications. They can achieve a flow adjustment as finely as 0.1%.

Installation and maintenance are additional considerations. Many users overlook the importance of a compact design for easy installation. A report indicates that nearly 30% of valve issues arise from improper installation. Lastly, always check the power requirements. Some valves need higher voltage, while others are more energy-efficient, fitting well into modern energy-saving systems. These aspects are essential in ensuring operational efficiency and minimizing costs.

Top 10 Electric Ball Valves: A Detailed Review

Electric ball valves are crucial in many systems. These devices control the flow of liquids and gases effectively. Their design allows quick operation, often requiring just a quarter turn. This results in rapid response times. Durable materials enhance their lifespan, but not all valves perform equally. Quality often varies.

Many electric ball valves feature user-friendly designs. This can make installation easier for professionals and DIYers alike. Some come with advanced options like position feedback. This ensures you know the status of the valve at all times. However, some models might not have robust sealing features. This can lead to leaks over time.

Factors such as size, pressure rating, and voltage cause confusion. Without proper research, you might choose the wrong valve. The application becomes critical here. In some situations, a low-power valve suffices, while others need a higher rating. Regular maintenance checks are essential, but many tend to overlook this. It's crucial to stay proactive. This helps avoid issues down the line and ensures system efficiency.

Top 10 Electric Ball Valves You Need to Know About

| Model | Size (Inches) | Voltage (V) | Material | Flow Rate (GPM) | Temperature Range (°F) | Control Type |

|---|---|---|---|---|---|---|

| Model A | 1" | 24V | Brass | 15 | -4 to 176 | On/Off |

| Model B | 2" | 120V | Stainless Steel | 30 | 14 to 194 | Modulating |

| Model C | 1.5" | 24V | PVC | 20 | 32 to 140 | On/Off |

| Model D | 3" | 120V | Brass | 45 | -20 to 200 | Modulating |

| Model E | 2.5" | 24V | Stainless Steel | 50 | 32 to 220 | On/Off |

| Model F | 1" | 12V | PVC | 10 | -4 to 140 | Modulating |

| Model G | 3" | 120V | Stainless Steel | 100 | -20 to 250 | On/Off |

| Model H | 2" | 24V | Brass | 60 | 32 to 180 | Modulating |

| Model I | 1.5" | 120V | Stainless Steel | 25 | -10 to 200 | On/Off |

| Model J | 2.5" | 24V | PVC | 35 | 32 to 150 | Modulating |

Comparative Analysis of Different Brands and Models

Electric ball valves offer precise control and automation for fluid management. Recent industry reports show that these valves can improve efficiency by up to 30% in various applications. The design features often include robust materials for durability and specialized actuators for responsiveness. However, differences in performance can be significant among models.

Some valves can operate in extreme temperatures, while others struggle in standard conditions. Users should consider factors like torque ratings and response times. For instance, a valve with a lower torque rating might fail under high-pressure scenarios. Not all models come with comprehensive support or warranties, which adds another layer of uncertainty for buyers.

Efficiency ratings are critical for energy consumption. Some valves are optimized to reduce power usage, achieving savings of up to 15% over their lifespan. Yet, this information is not always clear in product specifications. The actual performance often hinges on installation quality and system compatibility. Potential buyers should conduct thorough research before choosing a valve model to fit their needs.

Maintenance Tips for Ensuring Longevity of Electric Ball Valves

Electric ball valves are crucial for various industrial applications, but their longevity depends on proper maintenance. Regular inspection is key. Industry reports indicate that 30% of valve failures result from inadequate maintenance. A simple check can avert costly downtimes.

Tip: Regularly clean the valves to prevent debris buildup. Debris can hinder functionality and lead to leaks. Ensure all seals are in good condition, as worn seals can cause significant issues.

Another important aspect is temperature monitoring. Extreme temperatures can affect the valve's materials. Many electric ball valves operate optimally within a specific range. Operating outside this range can shorten their lifespan.

Tip: Schedule routine temperature checks. If the valve operates in an extreme environment, consider using thermal insulation. It can significantly enhance durability and efficiency.

Ultimately, while electric ball valves are robust, neglecting maintenance can lead to unexpected failures. Reflect on your current practices. Are they sufficient?